Storage for the mass market with high standards

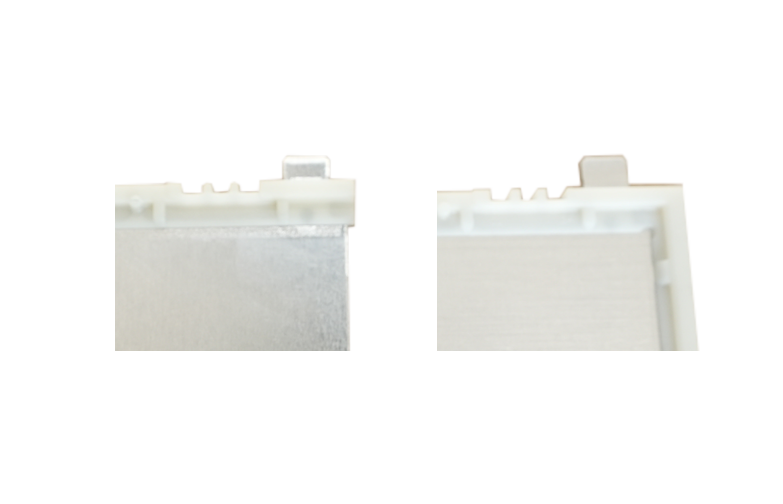

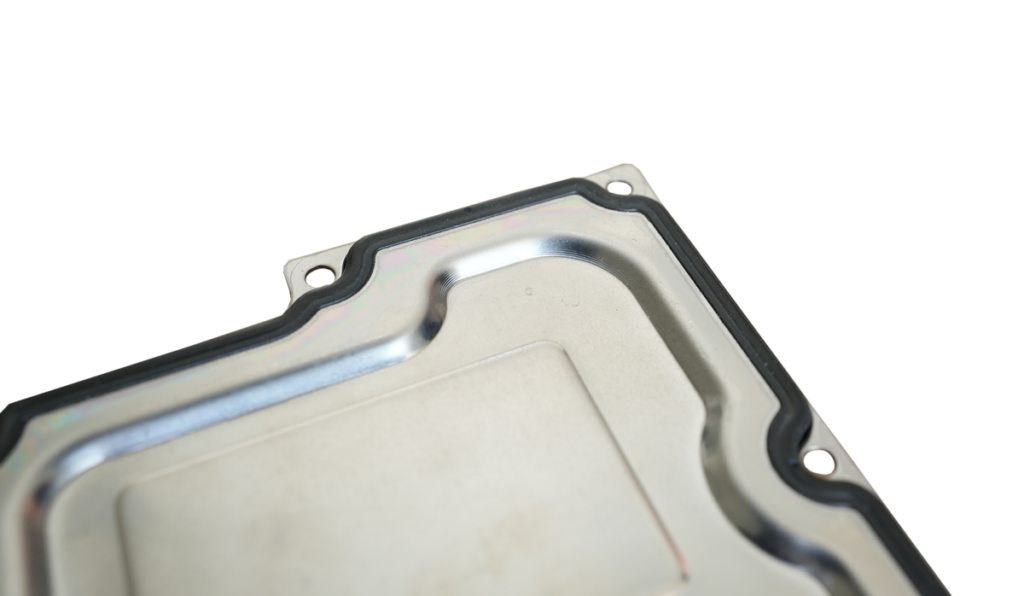

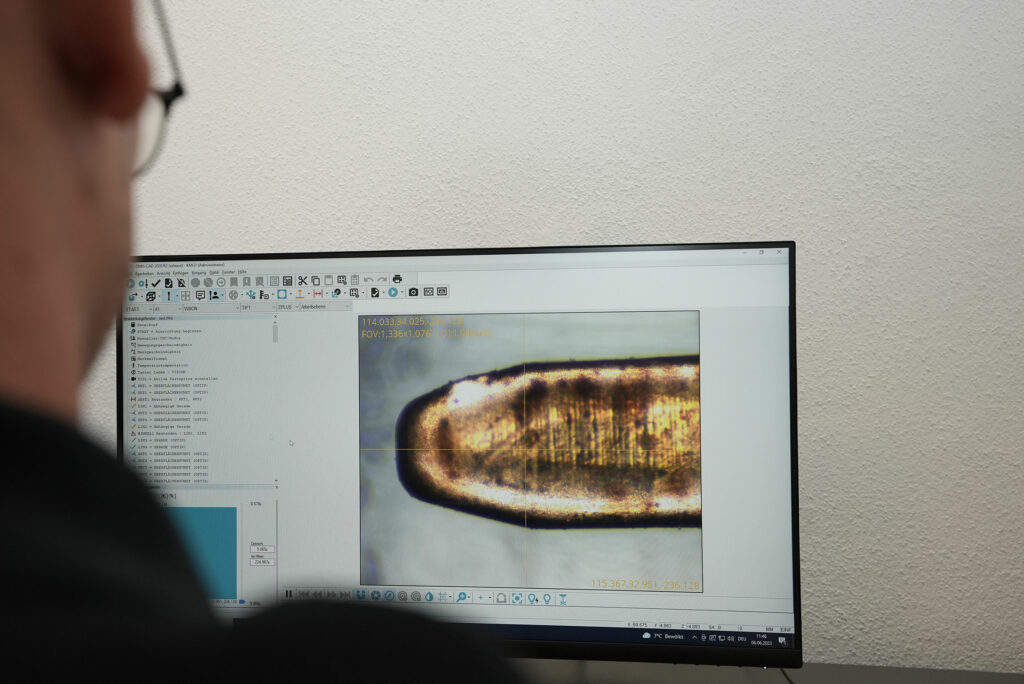

Mass markets are demanding in terms of both uninterrupted supply and consistently high quality. Your customers are difficult to satisfy. We help you to master this task. With our warehouse for raw materials, tools and finished parts, we match your call-offs with quantities. On time, high quality with a suitable logistics concept and sometimes unusual solutions (shared production). Deliveries are ensured from requirements with the same naturalness with which we help you with new developments and product discontinuation. All with the aim of providing our customers with an economically interesting collaboration.