Starting with support in application development, whether black box or specification sheet, through cooperation in determining suitable geometries and shapes of the parts for optimal FEM calculation.

We are at our customers’ disposal from the fulfillment of the function to the optimal integration into the subsequent processes (assembly and further processing). Whether CAD models, proof of strength, test procedures or prototypes. We supply the necessary know-how.

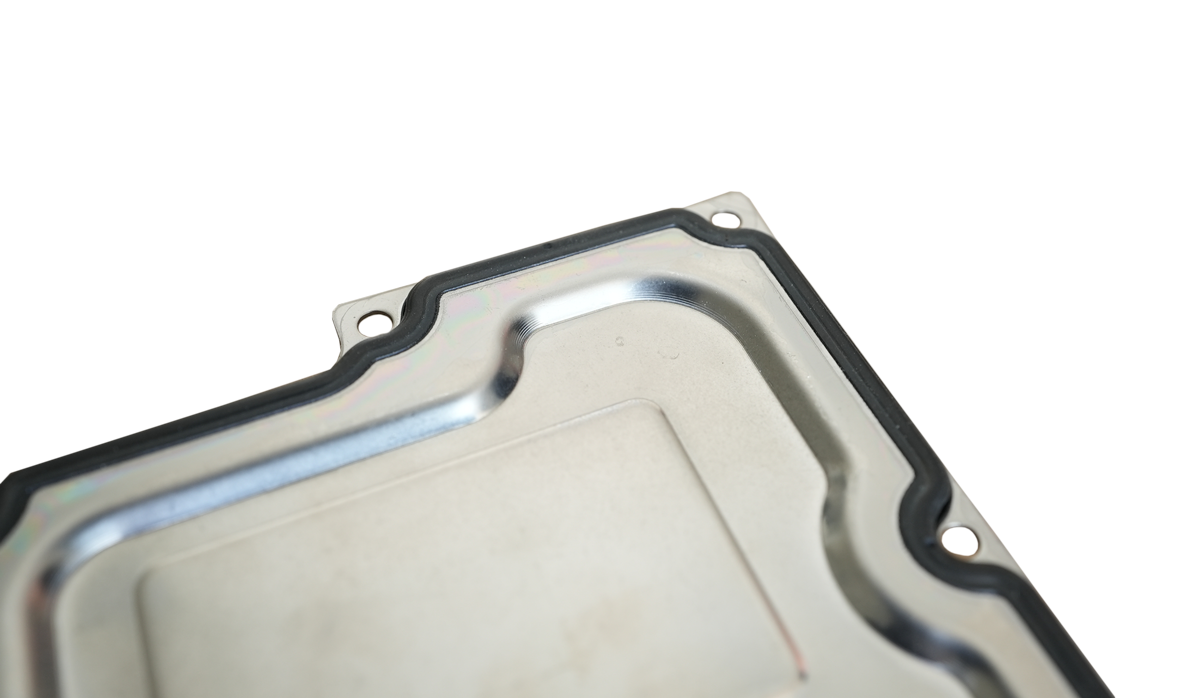

In order to gain new additional properties in a process, so-called hybrid parts could be your solution. Hybrid parts are metal parts that are produced in combination with a plastic. These are, for example, simple sheet metal covers with a rubber seal. The advantages of hybrid parts include optimized material usage, electrical conductivity through the stamped part and electrical insulation through the plastic.

Your work is full of responsibility. We help you to bear it. We produce prototypes from 3D data or design drafts with the same naturalness with which we help you with test selection and test execution. All with the aim of creating a convincing and economically interesting product.

We deliver according to your specifications and divisions.

We make use of highly specialized and highly productive tools as well as custom-built special systems and testing equipment from our own toolmaking and mechanical engineering departments. The full range of machines is available for this as well as the entire spectrum of materials and technical surface treatments.

Market access and new product launches are challenging. Your work is hard enough – we help you to get it done. We also produce small batches and pre-series from 3D data or design drafts with the same level of expertise with which we help you with large batches and product discontinuation.

Erma also offers all forming technology products in combination. Whether in combination with plastics, cables, surface finishes or DIN parts.

Whether precise mechanical assemblies, components for electrical use including electrical testing (e.g. HF seals or shielding), hybrid parts (metal – plastic connections) or thermally relevant components.

Erma works with customers to develop solutions to ensure long-term supply capability even beyond the end of large-scale production.

Ideally, you have a partner who thinks in advance about how the necessary supply can be maintained at a constant level of quality.

For us, this includes thinking about these things in advance. But even if it is “only” a matter of replacement requirements and the former series did not come from Erma, we deal with these tasks.

© 2024 | All Rights Reserved